Fire-resistant CAT8 bulk cables provide the essential speed, bandwidth, and safety for modern data center applications, ensuring optimal performance and compliance.

Table of Contents

- What Defines High-Performance Data Center Cabling Today?

- Why is CAT8 the Premier Choice for Data Center Applications?

- How Do Fire-Resistant Properties Elevate Data Center Safety?

- What Makes a Customized Cabling System the Optimal Solution?

- Selecting the Right Partner for Your Data Center Cabling Needs

What Defines High-Performance Data Center Cabling Today?

The modern data center is the backbone of the digital world, and its performance hinges directly on the quality of its physical infrastructure. The demands placed on this infrastructure are escalating at an unprecedented rate. Applications requiring immense bandwidth, ultra-low latency, and lightning-fast speeds—such as AI, machine learning, and high-frequency trading—are now commonplace. This necessitates a move towards network standards like 25GBASE-T and 40GBASE-T, which render older cabling categories obsolete.

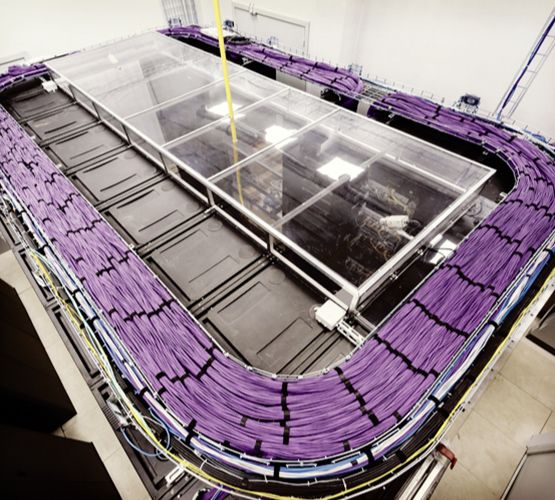

Beyond raw performance, data centers face significant physical challenges. As server racks become more densely populated, cable management becomes a critical factor in operational efficiency. Poorly managed, bulky cabling can obstruct airflow, leading to increased cooling costs and a higher risk of equipment failure due to overheating. Therefore, the ideal cabling solution must not only deliver on speed but also contribute to a streamlined, thermally efficient environment.

An equally important consideration is future-proofing. A data center is a long-term investment, and the cabling infrastructure installed today must be able to support the technologies of tomorrow. Selecting a cabling system that offers significant headroom for growth prevents the need for costly and disruptive rip-and-replace upgrades down the line, ensuring a stable and scalable network foundation for years to come.

Why is CAT8 the Premier Choice for Data Center Applications?

When addressing the stringent requirements of contemporary data centers, Category 8 (CAT8) cabling emerges as the definitive standard for high-speed, top-of-rack, and end-of-row network topologies. Its design is specifically tailored to handle the intense data throughput required within the confined distances of a server room environment.

Unpacking CAT8 Specifications

CAT8 represents a significant leap forward in twisted-pair copper cabling technology. It is engineered to support a frequency of up to 2000 MHz—four times that of CAT6A—enabling data transmission rates of up to 40 Gbps over distances of up to 30 meters. This makes it perfectly suited for connecting servers, switches, and storage area networks within the data center.

A key feature of CAT8 is its mandatory and superior shielding. Typically constructed as S/FTP (Screened/Foiled Twisted Pair), each individual pair of conductors is wrapped in foil, and an overall outer braid screen encases all four pairs. This robust construction is essential for mitigating alien crosstalk (ANEXT) and protecting against electromagnetic interference (EMI) in electrically noisy, high-density rack environments, ensuring signal integrity and reliable performance.

| Specification | CAT6A | CAT7 | CAT8 |

|---|---|---|---|

| Max Frequency | 500 MHz | 600 MHz | 2000 MHz |

| Max Data Rate | 10 Gbps @ 100m | 10 Gbps @ 100m | 40 Gbps @ 30m |

| Standard Shielding | U/FTP or F/UTP | S/FTP | S/FTP (Required) |

| Primary Application | General Office LAN | General LAN / AV | Data Center (Server-to-Switch) |

The Strategic Advantage of Bulk Cabling

For large-scale data center deployments, procuring CAT8 in bulk spools offers distinct advantages over pre-terminated patch cords. Bulk cabling is significantly more cost-effective when wiring an entire facility. More importantly, it provides unparalleled flexibility. Installers can cut cables to the precise length required for each run, which eliminates service loops and excess cable slack. This practice not only creates a cleaner, more professional installation but also vastly improves airflow within racks, contributing to better thermal management and lower energy consumption.

How Do Fire-Resistant Properties Elevate Data Center Safety?

While performance is paramount, the safety of personnel and the protection of invaluable assets are non-negotiable. In a data center, where vast amounts of cabling are concentrated in enclosed spaces, the fire-resistant properties of the cable jacket are a critical line of defense against catastrophic failure.

The Critical Role of Fire Safety in Network Infrastructure

Cabling can act as a conduit for fire, allowing flames to propagate rapidly through plenum spaces, risers, and cable trays. A fire event in a data center not only poses a direct threat from heat and flames but also an indirect threat from smoke and toxic fumes. Corrosive gases released by burning standard plastics can irreparably damage sensitive electronic components, even those far from the fire’s source. Adherence to strict building codes, such as the National Electrical Code (NEC) in the United States, is mandatory to mitigate these risks and ensure a safe operating environment.

Decoding Cable Jacket Fire Ratings

The material used for a cable’s outer jacket determines its behavior in a fire. Different ratings are assigned based on where the cable is intended to be installed. Understanding these ratings is crucial for ensuring compliance and safety.

- CMP (Communications Multipurpose Cable, Plenum): This is the highest fire rating for network cables. CMP-rated cables are designed for installation in “plenum” spaces—the areas used for air circulation, such as above dropped ceilings or below raised floors. They are treated with flame retardants and engineered to produce minimal smoke when exposed to fire.

- CMR (Communications Multipurpose Cable, Riser): Intended for vertical runs in a multi-story building, such as cabling that passes between floors through risers. CMR jackets are designed to prevent fire from spreading from one floor to another but are not as strictly regulated as CMP.

- LSZH (Low Smoke Zero Halogen): This rating is especially important for protecting human life and sensitive equipment. When an LSZH cable is exposed to fire, it emits very little smoke and, crucially, no toxic halogen compounds (like chlorine or fluorine). This preserves visibility for evacuation and prevents the release of corrosive gases that destroy electronics.

| Property | CMP (Plenum) | CMR (Riser) | LSZH |

|---|---|---|---|

| Flame Spread | Very Low | Low | Low |

| Smoke Emission | Very Low | Medium | Extremely Low |

| Halogen/Toxicity | Low | High | Zero Halogen / Low Toxicity |

| Typical Application | HVAC Air Spaces | Vertical Shafts | Enclosed Public/Sensitive Areas |

What Makes a Customized Cabling System the Optimal Solution?

Every data center has a unique architecture, specific environmental conditions, and distinct operational protocols. A one-size-fits-all approach to cabling is often inefficient and can lead to compromises in performance, safety, and manageability. This is where customized cabling systems provide a definitive advantage.

Moving Beyond Off-the-Shelf Products

Standard, pre-packaged cables rarely meet the exact needs of a complex data center build. Off-the-shelf products can result in improper lengths, which complicates cable management, or lack the specific jacket material required for a particular environment. For streamlined operations and long-term maintenance, cables often need to be color-coded for different functions or printed with specific identifiers. These are features that standard products simply do not offer.

The Power of OEM/ODM Partnerships

Engaging in an OEM/ODM (Original Equipment Manufacturer/Original Design Manufacturer) partnership with a specialized cable producer unlocks a level of precision and quality control that is otherwise unattainable. It allows data center operators and installers to specify their exact requirements and receive a product perfectly tailored to their project.

At D-Lay Cable, we specialize in providing these bespoke solutions. With over a decade of manufacturing experience and a deep portfolio of certifications including UL, ETL, CPR, CE, and RoHS, we deliver customized CAT8 systems that align perfectly with your data center’s needs. Our OEM/ODM capabilities include:

- Tailored Jacket Materials: We assist you in selecting the ideal jacket compound—whether it’s a specific CMP formulation for plenum spaces, a ruggedized material for industrial settings, or LSZH for maximum personnel safety.

- Custom Printing & Labeling: Simplify asset management and troubleshooting with custom text, logos, and sequential numbering printed directly on the cable jacket. This makes identifying specific runs within dense racks effortless.

- Specific Performance Requirements: We can engineer and manufacture cables that not only meet but exceed the TIA and ISO/IEC standards, providing additional performance headroom for your most critical applications.

By partnering with a manufacturer like D-Lay Cable, you gain direct control over the quality, performance, and physical characteristics of your cabling infrastructure, ensuring it is built for purpose without compromise.

Selecting the Right Partner for Your Data Center Cabling Needs

The choice of a cabling manufacturer is as critical as the choice of the cable itself. The right partner provides not just a product, but also expertise, reliability, and the assurance of long-term performance. A meticulous evaluation process is essential to ensure your investment is sound.

Key Criteria for Evaluating a Cable Manufacturer

When selecting a supplier for your critical data center infrastructure, several factors must be carefully considered to ensure you receive a product that is safe, reliable, and high-performing.

- Certifications and Compliance: This is the ultimate proof of quality and safety. A reputable manufacturer must provide clear documentation of adherence to performance standards like TIA-568 and ISO/IEC 11801. Furthermore, safety and materials compliance ratings such as UL, ETL, CPR, and RoHS are non-negotiable indicators of a trustworthy and globally recognized supplier.

- Manufacturing Expertise: Producing high-frequency CAT8 S/FTP cable is a complex process. Look for a manufacturer with a proven history and specialized facilities dedicated to network cabling. Their technical knowledge is invaluable in developing a product that consistently performs under pressure.

- Customization Capabilities: A true partner should be able to accommodate your specific project needs. Assess their flexibility and responsiveness to OEM/ODM requests, from jacket color and printing to conductor specifications and packaging.

- Quality Control: Ask about their testing procedures. Rigorous quality control, including 100% Fluke testing for patch cords or comprehensive testing for bulk cable batches, guarantees that every meter of cable shipped meets the specified performance criteria.

The D-Lay Cable Commitment to Excellence

At D-Lay Cable, we build our reputation on these pillars of quality, expertise, and customer-centric service. We integrate advanced manufacturing technologies with stringent, multi-stage quality control to produce fire-resistant CAT8 bulk cables that form the bedrock of a modern, high-performance network. Our solutions are more than just components; they are the foundation of a reliable, safe, and scalable infrastructure, meticulously customized to the unique specifications of your data center environment.