Custom CAT7 aerospace cables are engineered with radiation-hardened materials and advanced shielding to ensure 10 Gbps data integrity in harsh flight environments.

Table of Contents

- The Unyielding Demand for High-Speed Data in Modern Aerospace

- Why Standard CAT7 Cables Fail in Aerospace Environments

- Understanding Radiation Effects on Ethernet Cabling

- Designing Radiation-Resistant CAT7 Cables: A Multi-Layered Approach

- The Role of Customization in Mission-Critical Applications

- Partnering with an Expert for Aerospace Cable Solutions

The aerospace industry is undergoing a profound data-driven transformation. From advanced avionics and in-flight connectivity to high-resolution earth observation satellites, the need for rapid, reliable data transmission has never been greater. Category 7 (CAT7) cabling, with its capability to deliver 10 Gbps speeds, offers the bandwidth necessary for these next-generation systems. Yet, the extreme conditions of atmospheric flight and space operation render standard commercial-grade cables entirely unsuitable. A specialized approach, focusing on custom, radiation-resistant design, is essential for mission success.

The Unyielding Demand for High-Speed Data in Modern Aerospace

The backbone of any modern aircraft or spacecraft is its data network. The immense volume of information generated and processed requires robust, high-bandwidth interconnects. CAT7 cabling standards provide a significant performance leap, supporting frequencies up to 600 MHz and enabling the 10GBASE-T standard. This capability is critical for several key aerospace applications.

In commercial and military aviation, high-speed networks support everything from real-time flight control data and advanced sensor fusion to high-definition in-flight entertainment (IFE) systems and crew communications. For satellite and space exploration missions, reliable 10 Gbps links are indispensable for transmitting scientific data, telemetry, and high-resolution imagery, where data loss is not an option. The superior shielding inherent in the CAT7 specification provides a foundational advantage in mitigating crosstalk and interference, but it is only the starting point for a true aerospace-grade solution.

Why Standard CAT7 Cables Fail in Aerospace Environments

An off-the-shelf CAT7 cable, while excellent for a data center, would quickly become a point of failure in an aerospace platform. The operational environment subjects components to a combination of physical and electromagnetic stresses far beyond their design parameters.

Extreme Temperatures and Vibration

Aerospace platforms experience dramatic temperature fluctuations, from cryogenic lows in space to extreme heat near engine components or during atmospheric re-entry. Standard PVC or LSZH (Low Smoke Zero Halogen) jackets become brittle in the cold and can outgas or lose structural integrity when hot. Continuous, high-frequency vibration during launch and flight can cause conductor fatigue, connector loosening, and eventual signal failure in cables not designed for such mechanical stress.

Electromagnetic Interference (EMI) and Crosstalk

Aircraft and spacecraft are dense with powerful electronic systems, including radios, radar, and power distribution networks, all of which generate significant electromagnetic interference. While CAT7’s S/FTP (Screened/Foiled Twisted Pair) construction offers excellent protection against common EMI, it may be insufficient to block the intense, wide-spectrum noise found in a compact avionics bay. Without specialized shielding, this interference can corrupt data packets, leading to system errors or complete communication loss.

The Critical Challenge of Ionizing Radiation

Outside the protection of Earth’s atmosphere, electronic components are exposed to a constant barrage of ionizing radiation from galactic cosmic rays, solar flares, and trapped radiation belts. This invisible threat poses a severe risk to data cable integrity. Radiation can physically degrade the insulating materials and, more critically, directly interfere with the electrical signals carrying the data, causing bit-flips and data corruption that can jeopardize a mission.

Understanding Radiation Effects on Ethernet Cabling

The impact of radiation on cabling is a complex issue that manifests in two primary ways: long-term material degradation and immediate data corruption. Both must be addressed in the design of any aerospace-grade data cable.

Total Ionizing Dose (TID) and Material Degradation

Total Ionizing Dose (TID) refers to the cumulative radiation absorbed by a material over its operational lifetime. For polymers used in cable jackets and dielectrics, such as PVC, high TID levels cause chain scission and cross-linking. This process makes the material brittle, prone to cracking, and compromises its insulating properties. A cracked jacket exposes the shielding and conductors to moisture, vibration, and other physical damage, leading to a complete cable failure. A specialized material selection is the only way to counteract TID effects.

Single Event Effects (SEE) and Data Corruption

Single Event Effects (SEE) occur when a single high-energy particle passes through a semiconductor or, in the case of a cable, induces a transient voltage pulse in a conductor. This can cause a bit to flip (a 0 becomes a 1, or vice versa) within the data stream. While error-correction protocols can handle some bit-flips, a high-radiation environment can overwhelm these systems, resulting in corrupted data packets. For mission-critical commands or irreplaceable scientific data, such corruption is unacceptable. Advanced shielding and cable construction are vital to minimize the occurrence of SEEs.

Designing Radiation-Resistant CAT7 Cables: A Multi-Layered Approach

Creating a CAT7 cable assembly that can survive and perform in aerospace applications requires a holistic design philosophy that addresses electrical, mechanical, and environmental challenges simultaneously. At D-Lay Cable, our engineering process focuses on building robust, mission-ready interconnects from the inside out.

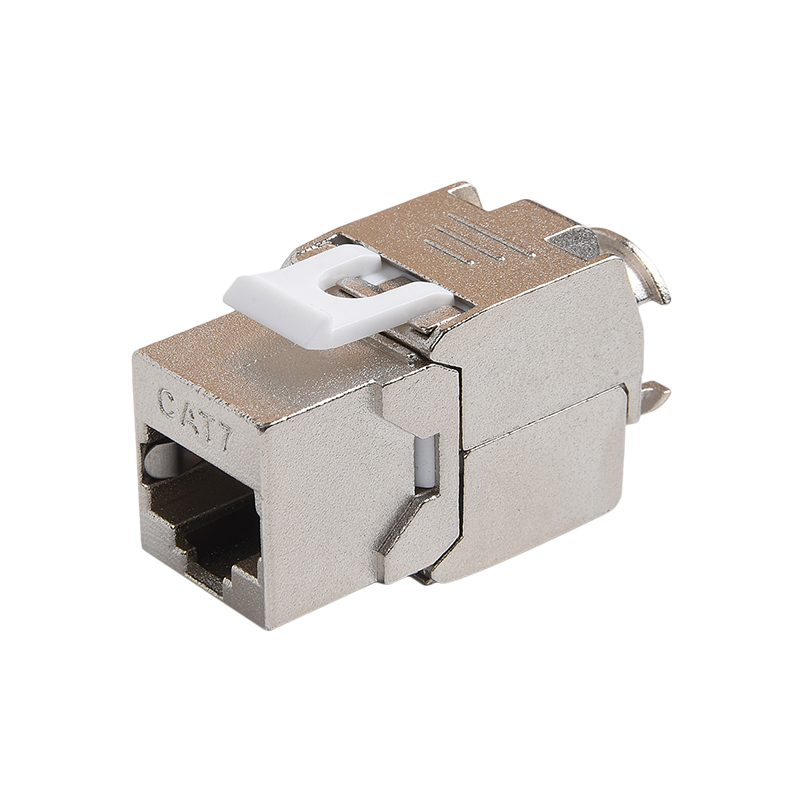

Advanced Shielding Techniques for EMI and Radiation

The standard foil and braid shielding of CAT7 is enhanced for aerospace use. This often involves using silver-plated copper braids for improved shield effectiveness at high frequencies. A multi-layered shielding approach, potentially incorporating specialized materials, provides superior protection against both ambient EMI and radiation-induced signal noise. The goal is to create a comprehensive Faraday cage around the twisted pairs, preserving signal integrity against all external threats.

Selecting Radiation-Hardened Materials (Jacket & Dielectric)

Material science is at the heart of radiation-resistant cable design. Instead of standard plastics, specialized polymers are used for the cable jacket and the dielectric insulator surrounding the conductors.

- ETFE (Ethylene tetrafluoroethylene), often known by the brand name Tefzel®, is a popular choice for its excellent radiation resistance, wide temperature range, and mechanical toughness.

- FEP (Fluorinated Ethylene Propylene) and PFA (Perfluoroalkoxy) are other fluoropolymers offering superior performance in extreme environments.

These materials resist the embrittlement caused by TID and maintain their dielectric properties, ensuring consistent electrical performance over the mission’s lifespan.

| Component | Standard Commercial CAT7 | Aerospace-Grade Custom CAT7 |

|---|---|---|

| Jacket Material | PVC or LSZH | ETFE (Tefzel®), FEP, PFA |

| Conductor Plating | Bare Copper | Silver-Plated or Nickel-Plated Copper |

| Shielding | Aluminum Foil, Tinned Copper Braid | Silver-Plated Copper Braid, Enhanced Foil Coverage |

| Temperature Range | ~ -20°C to 75°C | ~ -65°C to 200°C |

Ruggedized Connectors and Strain Relief

A cable is only as strong as its termination. For aerospace applications, standard RJ45 connectors are replaced with ruggedized, high-reliability connectors like those conforming to MIL-DTL-38999 or ARINC specifications. These connectors feature robust metal shells, positive locking mechanisms, and environmental sealing to protect against moisture, dust, and vibration. Expert overmolding and strain relief are applied to the backshell, ensuring the termination point can withstand extreme mechanical stress without compromising the electrical connection.

The Role of Customization in Mission-Critical Applications

No two aerospace platforms are identical. The unique geometries, system layouts, and performance requirements of each aircraft or satellite demand a custom-fit solution. This is where a specialist cable assembly provider becomes a critical partner.

Tailoring Lengths and Configurations

Custom assemblies are built to precise lengths, eliminating service loops that add unnecessary weight and introduce potential points of failure. Complex harnesses can be designed with multiple breakouts, varied connector types, and integrated mounting points, streamlining installation and maintenance within tightly packed avionics bays. This level of tailoring is impossible to achieve with off-the-shelf components.

Integration with Specific Avionics Systems

Working with a custom cable manufacturer ensures that every assembly is perfectly matched to the systems it connects. Impedance, propagation delay, and insertion loss are all optimized for the specific application, whether it’s a high-speed link between a flight computer and a sensor array or a backbone for a satellite’s communication payload. This guarantees not just compatibility, but peak performance.

Adherence to Aerospace and Military Standards (ARINC, MIL-SPEC)

Custom assemblies are designed and manufactured in accordance with stringent industry standards. Adherence to specifications such as ARINC for avionics or MIL-SPEC for military hardware is not optional. These standards govern every aspect of the cable’s design, from the materials used to the testing procedures required, ensuring the final product is certifiably reliable and safe for flight.

Partnering with an Expert for Aerospace Cable Solutions

Developing a robust, radiation-resistant CAT7 cable assembly requires deep expertise in materials science, electrical engineering, and the specific demands of the aerospace industry. The intricate balance between performance, durability, and weight must be carefully managed at every stage of the design and manufacturing process.

At D-Lay Cable, we specialize in engineering and manufacturing custom cable solutions for the most demanding applications. Our team works closely with aerospace engineers to understand their unique challenges, delivering high-reliability CAT7 and other data cable assemblies that are built to perform flawlessly from the tarmac to low Earth orbit and beyond. By combining cutting-edge materials with meticulous craftsmanship and rigorous testing, we provide the critical data links that modern aerospace systems depend on.