As a leading provider of high-quality networking solutions at DlayCable, we often encounter a question that pops up frequently on tech forums and Reddit threads: “Do my Ethernet cables, especially my trusty old Cat5e, actually wear down?” It’s a valid question. You plug it in, and it just works… until it doesn’t. While a cable doesn’t have a battery or moving parts, the answer is more complex than a simple yes or no.

The short answer is: Ethernet cables don’t “wear out” from age alone, but they absolutely can and do fail due to physical and environmental factors. Let’s dive into the real reasons your connection might be suffering and when it’s time for an upgrade.

Table of Contents

- The Myth of “Wearing Out” vs. The Reality of Degradation

- The #1 Culprit: Physical Damage

- Silent Saboteurs: Environmental Factors

- The Performance Problem: Is Your Cat5e Cable Obsolete?

- How to Tell if Your Ethernet Cable is Failing

- The DlayCable Difference: Why Quality Matters for Longevity

The Myth of “Wearing Out” vs. The Reality of Degradation

Unlike a tire that loses tread with every mile, a stationary Ethernet cable made of copper and plastic isn’t actively degrading just by sitting there. The copper conductors and insulation are incredibly stable. If a cable is installed correctly in a climate-controlled wall and never touched, it could theoretically last for decades without any loss in performance. However, that’s rarely the real-world scenario.

Failure isn’t about the cable “expiring.” It’s about damage, stress, and environmental exposure that compromises its ability to transmit data flawlessly.

The #1 Culprit: Physical Damage

Most Ethernet cable failures we see are due to physical stress. These are the most common ways a cable gets damaged, often without you even realizing it.

1. Extreme Bends and Kinks

Every Ethernet cable has a “minimum bend radius.” Bending it too sharply, especially at a 90-degree angle around a sharp corner, can stretch the copper wires inside, alter their geometry, and even cause micro-fractures. This increases resistance and creates “noise,” leading to data packet loss and slower speeds.

2. Crushing and Pinching

Running a cable under a heavy desk leg, through a slammed door jamb, or stapling it too tightly to a wall can crush the internal wire pairs. This compromises the insulation and the precise twisting of the pairs, which is critical for preventing crosstalk and interference.

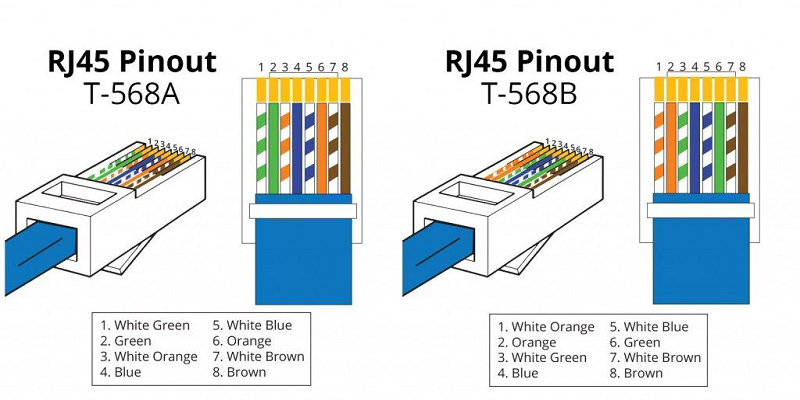

3. Strain on the Connector (RJ45)

The connector is the weakest point. The small plastic locking tab is notoriously easy to break off, leading to a loose connection that can drop intermittently. Furthermore, repeatedly plugging and unplugging the cable wears down the gold-plated contacts, and pulling on the cable (instead of the connector boot) can sever the connection between the wires and the pins inside the RJ45 head.

4. Accidental Cuts and Abrasions

This one is obvious but common. A vacuum cleaner, a pet chewing on the cord, or rubbing against a sharp edge can slice through the outer jacket and damage the conductors within.

Silent Saboteurs: Environmental Factors

If your cable is running through a less-than-ideal environment, it’s fighting a battle against the elements.

- UV Exposure: Standard indoor-rated (CM/CMG) cables are not meant for sunlight. UV rays will break down the PVC jacket, making it brittle and cracked, exposing the delicate inner wires to the elements.

- Moisture and Humidity: Water is the enemy of electronics. Moisture can lead to corrosion on the copper contacts of the RJ45 connector, impeding the electrical signal. In extreme cases, water wicking into a damaged jacket can degrade the conductors themselves.

- Extreme Temperatures: Constant exposure to high heat or freezing temperatures can cause the cable’s jacket to expand and contract, eventually leading to brittleness and cracking.

Pro Tip from DlayCable: If you need to run a cable outdoors, in a damp basement, or through an air plenum, always use a cable specifically designed for that purpose. We offer a wide range of outdoor (CMX) and plenum-rated (CMP) cables that feature robust, weather-resistant jackets to ensure a long, reliable service life.

The Performance Problem: Is Your Cat5e Cable Obsolete?

Sometimes, a cable isn’t “bad,” it’s just outdated. Cat5e was designed for speeds up to 1 Gigabit per second (Gbps). For years, this was more than enough. Today, with multi-gig internet plans, high-speed local file transfers, and demanding streaming, Cat5e is now the bottleneck in many modern networks.

Your cable might be perfectly functional, but it’s “worn out” in terms of performance. Upgrading to Cat6 or Cat6a can unlock speeds of 10 Gbps, offering a significant and noticeable improvement. They also feature better shielding and tighter wire twists, making them more resilient to electronic interference (EMI) from power cords and appliances.

How to Tell if Your Ethernet Cable is Failing

Suspect a cable is the root of your internet woes? Look for these signs:

- Slower than expected speeds: Run a speed test. If it’s far below what you’re paying for, the cable could be the issue.

- Intermittent connection drops: If your connection randomly disconnects and reconnects, it often points to a loose or damaged connector.

- No connection at all: The most obvious sign. Your device reports “No Cable Connected” even when plugged in.

- Visible damage: Inspect the cable for any of the physical issues mentioned above—kinks, flattened sections, broken tabs, or cuts.

The easiest way to diagnose is to simply swap the suspect cable with a new, known-good one. If the problem disappears, you’ve found your culprit.

The DlayCable Difference: Why Quality Matters for Longevity

While any cable can be damaged, a well-made cable is far more resilient. This is where investing in quality from a trusted supplier like DlayCable pays off.

- Pure Bare Copper Conductors: We use 100% pure copper in our cables, not cheap Copper Clad Aluminum (CCA). Pure copper is more durable, flexible, and a superior conductor, ensuring signal integrity and resistance to physical stress.

- Robust Construction: Our cables feature durable, high-quality jackets and precision-molded connector boots that protect the locking tab and relieve strain on the connection point.

- Strict Certifications: Our products are UL Listed and RoHS compliant, meaning they meet the highest industry standards for safety, performance, and material quality.

- The Right Cable for the Job: From flexible patch cords to heavy-duty outdoor and plenum-rated bulk cable, we provide the correct, purpose-built solution to ensure your network is reliable for years to come.

Conclusion

So, do Ethernet Cat5e cables wear down? Not from old age, but from the rigors of the real world. Physical damage, environmental exposure, and performance obsolescence are the true enemies of a stable connection. By handling your cables with care and choosing high-quality, certified products built for your specific environment, you can ensure your network’s physical foundation is solid, secure, and ready for the future.

Ready to eliminate a potential bottleneck? Explore our comprehensive range of reliable, high-performance Ethernet cables at DlayCable.com and build a network that lasts.