The primary difference between flame resistant and flame retardant cables lies in their performance during a fire: flame retardant cables are designed to resist the spread of fire by self-extinguishing once the fire source is removed, while flame resistant cables are engineered to maintain circuit integrity and continue operating for a specified period during a fire. Understanding this distinction is not just a matter of terminology; it’s a critical factor in ensuring electrical system safety, compliance with building codes, and the protection of life and property.

While both cable types play a vital role in fire safety, their functions are fundamentally different. A flame retardant cable’s main job is to prevent a fire from propagating along its length, thereby containing the blaze. A flame resistant cable’s job is to keep critical systems—like fire alarms, emergency lighting, and smoke extractors—powered and operational, even when engulfed in flames, to facilitate a safe evacuation.

Table of Contents

- Understanding the Core Distinction: A Quick Overview

- What Are Flame Retardant Cables? (Slowing the Spread)

- What Are Flame Resistant Cables? (Maintaining Functionality in a Fire)

- Key Differences Summarized: A Head-to-Head Comparison

- How to Choose the Right Cable: Application is Everything

- The Role of LSZH (Low Smoke Zero Halogen) in Fire Safety

- Conclusion: Making the Right Choice for Safety and Compliance

- Frequently Asked Questions (FAQ)

Understanding the Core Distinction: A Quick Overview

To put it simply, think of the roles people play in a fire emergency. A flame retardant cable acts like a firebreak—its primary goal is to stop the fire from spreading. Once the initial source of the flame is gone, the cable’s special jacketing material will self-extinguish, preventing it from acting as a fuel source that carries fire from one room to another. Its own functionality is secondary to preventing the fire’s progression.

On the other hand, a flame resistant cable (often called a fire-rated or circuit integrity cable) acts like a firefighter—its job is to continue working in the midst of the fire. These cables are built to withstand extreme temperatures and direct flame exposure for a specific duration (e.g., 30, 60, or 120 minutes) without losing their electrical properties. This ensures that life-saving systems remain operational during an emergency.

What Are Flame Retardant Cables? (Slowing the Spread)

Flame retardant cables are the most common type of fire performance cable used in general-purpose wiring within buildings. Their design is focused on passive fire protection. The goal isn’t to survive the fire indefinitely but to limit its contribution to the fire’s growth and spread, providing valuable time for evacuation and response. If a short circuit causes a cable to ignite, its flame-retardant properties will ensure the fire doesn’t travel up the cable and into other areas.

How Do Flame Retardant Cables Work?

The magic of flame retardant cables lies in the chemical composition of their insulation and jacketing materials. These materials, typically PVC (Polyvinyl Chloride) or similar polymers, are treated with chemical additives. When exposed to high heat or flame, these additives trigger a chemical reaction that inhibits combustion. This can happen in several ways:

- Gas Phase Inhibition: The chemicals release non-combustible gases that displace the oxygen around the flame, effectively suffocating it.

- Condensed Phase Charring: The material forms a solid, carbonaceous layer (char) on its surface. This char acts as an insulating barrier, shielding the inner polymer from the heat and cutting off the fuel supply.

- Cooling Effect: Some additives release water molecules when heated, which creates a cooling effect on the cable’s surface, lowering its temperature below the point of combustion.

Once the external flame source is removed, these mechanisms cause the cable to stop burning on its own. This self-extinguishing property is the defining characteristic of a flame retardant cable.

Common Standards and Tests for Flame Retardant Cables

To ensure a cable meets flame retardant criteria, it must pass rigorous testing. These tests typically involve applying a flame to a single cable or a bundle of cables for a set duration and observing how far the fire spreads. Key standards include:

- IEC 60332: An international standard series that tests the flame propagation characteristics of single (IEC 60332-1) and bunched (IEC 60332-3) cables.

- UL 1685 (VTFT – Vertical-Tray Flame Test): A North American standard that assesses the flame spread and smoke release of cables installed vertically in a tray, simulating a real-world installation.

- IEEE 1202: A standard similar to UL 1685, also widely used in North America for industrial applications.

What Are Flame Resistant Cables? (Maintaining Functionality in a Fire)

Flame resistant cables, or circuit integrity cables, are a specialized and robust type of electrical cable designed for a much more demanding task: to keep working when everything else is burning. Their construction is focused on active fire protection, ensuring that the electrical circuits they serve can power critical life-safety systems during an evacuation or emergency response. These are the cables you rely on to power exit signs, fire alarms, ventilation systems, and water pumps when they are needed most.

How Do Flame Resistant Cables Maintain Integrity?

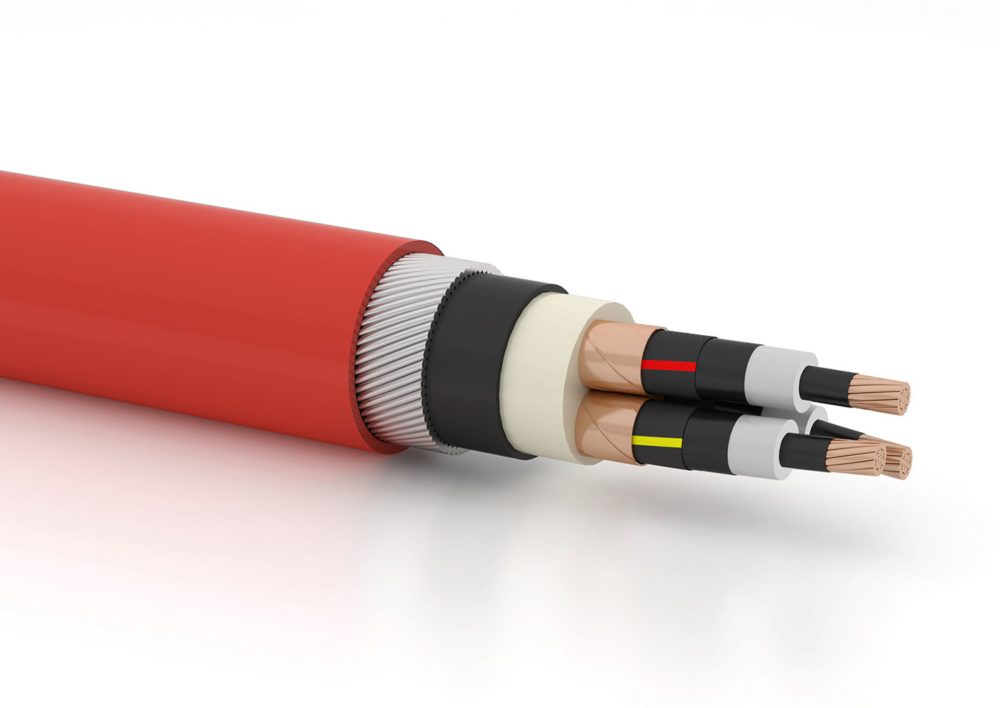

Unlike flame retardant cables, which rely on chemical additives in their jackets, flame resistant cables use physical barriers to protect the core conductors. Their construction is fundamentally different and more complex, often involving multiple layers of specialized materials:

- Mica Tape: The most common method involves wrapping the copper conductors with a heat-resistant glass-mica tape. When exposed to extreme heat, the mica transforms into a hard, insulating ceramic-like ash. This “ash skeleton” physically holds the conductors in place and prevents them from short-circuiting against each other or a metal conduit, even after the outer insulation has completely burned away.

- Silicone Rubber: Some designs use specially formulated silicone compounds that, like mica, turn into a non-conductive, insulating ash under fire conditions.

- Robust Construction: These cables often feature additional layers of fire-resistant fillers, sheaths, and sometimes even armor to provide mechanical protection during a fire, protecting them from falling debris or the spray from fire hoses.

Common Standards and Tests for Flame Resistant Cables

Testing for flame resistance is far more severe than for flame retardancy. It doesn’t just measure fire spread; it tests the cable’s ability to maintain a continuous electrical current while being actively burned. Standards often specify a temperature, a duration, and sometimes even mechanical shock and water spray.

- IEC 60331: This standard tests a cable’s ability to maintain circuit integrity while exposed to a flame at 750°C (or higher in some variations) for a specified time.

- BS 7629: A British standard for fire-resistant cables that includes tests for direct flame, mechanical shock, and water spray to simulate real-world fire conditions.

- UL 2196: A stringent North American standard for fire-resistive cables, requiring them to maintain functionality for up to 2 hours at temperatures reaching 1010°C (1850°F), followed by the impact from a fire hose stream.

Key Differences Summarized: A Head-to-Head Comparison

To provide a clear, at-a-glance reference, here is a table comparing the key attributes of flame retardant and flame resistant cables.

| Attribute | Flame Retardant Cables | Flame Resistant Cables |

|---|---|---|

| Primary Function | To prevent the spread of fire (passive protection). | To continue operating during a fire (active protection). |

| Behavior in Fire | Designed to self-extinguish after the flame source is removed. Will eventually burn and fail. | Maintains circuit integrity for a specified time (e.g., 1-2 hours) at high temperatures. |

| Construction | Uses chemical additives in the insulation/jacket (e.g., FR-PVC). | Uses physical fire barriers like mica tape or special silicone around conductors. |

| Key Standards | IEC 60332, UL 1685, IEEE 1202. | IEC 60331, BS 7629, UL 2196. |

| Typical Applications | General power and control wiring in residential and commercial buildings, data centers. | Fire alarm systems, emergency lighting, smoke extraction fans, sprinkler pumps, public address systems. |

| Cost | Lower cost, widely available. | Significantly higher cost due to specialized materials and construction. |

How to Choose the Right Cable: Application is Everything

The decision to use a flame retardant or flame resistant cable is not a matter of choice but is dictated by building codes, safety regulations, and the specific application of the circuit. Mismatching the cable type can lead to catastrophic system failure, non-compliance, and severe safety hazards.

When Should You Use Flame Retardant Cables?

Flame retardant cables are the standard for most electrical installations where the primary fire safety concern is preventing the wiring itself from becoming a pathway for fire. They should be used for:

- General power distribution in buildings.

- Lighting circuits (non-emergency).

- Data and communication cabling in plenums and risers.

- Control wiring for non-critical systems.

The use of flame retardant cables in vertical shafts and cable trays is particularly important, as this prevents a fire on a lower floor from quickly spreading to upper floors via the wiring.

When Are Flame Resistant Cables Necessary?

Flame resistant cables are mandated for any system that is essential for life safety and must function during a fire. Choosing these cables is a non-negotiable requirement for:

- Fire Alarm and Detection Systems: To ensure the alarm can sound and alert occupants.

- Emergency and Egress Lighting: To illuminate escape routes during a power outage or fire.

- Pressurization Fans and Smoke Extractors: To keep stairwells and escape routes free of smoke.

- Firefighter Elevators and Water Pumps: To provide emergency services with the tools they need to fight the fire.

- Public Address and Voice Alarm (PAVA) Systems: To allow for clear evacuation instructions to be broadcast.

In these critical applications, a flame retardant cable would fail within minutes of fire exposure, rendering the life-saving system useless. Only a flame resistant cable can provide the necessary circuit integrity.

The Role of LSZH (Low Smoke Zero Halogen) in Fire Safety

It’s important not to confuse LSZH (Low Smoke Zero Halogen) properties with flame retardancy or resistance. LSZH refers to the characteristics of the smoke produced when a cable burns. Traditional PVC cables release thick, black, toxic smoke containing halogen gases like hydrogen chloride, which can obscure vision and are highly corrosive and dangerous to inhale.

LSZH cables are made from compounds that produce very little light-colored smoke and no toxic halogen gases when they burn. This is a separate, additional property. A cable can be:

- Flame Retardant and LSZH.

- Flame Resistant and LSZH.

LSZH cables are specified for use in enclosed public spaces like subways, airports, hospitals, and high-rise buildings where toxic smoke poses a significant threat to life. While crucial for safety, being LSZH does not, by itself, define a cable’s ability to resist the spread of fire or maintain circuit integrity.

Conclusion: Making the Right Choice for Safety and Compliance

In the world of electrical safety, the distinction between flame retardant and flame resistant is absolute. Flame retardant cables are your first line of defense, designed to contain a fire by preventing its spread along wiring. Flame resistant cables are your critical lifeline, built to endure the fire and keep essential safety systems running.

Ultimately, selecting the correct cable comes down to understanding the specific requirements of the application and adhering to the relevant building codes and safety standards. By correctly identifying whether a circuit’s primary need is to limit fire propagation or to guarantee functionality during a fire, engineers, installers, and facility managers can ensure the highest levels of safety and build resilient, compliant electrical systems.

Frequently Asked Questions (FAQ)

1. Can I use a flame resistant cable in a general-purpose application?

Yes, but it is typically not cost-effective. Flame resistant cables are significantly more expensive and often more difficult to install than flame retardant cables. While they offer superior performance in a fire, their cost is only justified for critical life-safety circuits.

2. Is “fireproof” the same as flame resistant?

While the term “fireproof” is often used colloquially, the industry standard term is “flame resistant” or “fire-rated.” No material is truly fireproof indefinitely. Flame resistant cables are rated to survive for a specific duration (e.g., 2 hours) at a specific temperature, as defined by standards like UL 2196 or IEC 60331.

3. Are all LSZH cables flame retardant?

Most cables designed with LSZH compounds are also engineered to be flame retardant to meet building codes. However, the two properties are distinct. You must always check the cable’s datasheet to confirm it meets the required flame retardant standards (e.g., IEC 60332) in addition to being LSZH.

4. What does “circuit integrity” mean?

Circuit integrity is the ability of a cable to continue carrying electrical current and transmitting data without a short circuit or open circuit, even while being exposed to direct flame. This is the defining performance characteristic of a flame resistant cable.