Choosing a reliable cable OEM/ODM manufacturer in China is a critical decision that hinges on a structured vetting process. To ensure success, you must first precisely define your product specifications and budget, then identify potential suppliers through B2B platforms and industry trade shows. The most crucial phase involves conducting thorough due diligence by verifying business licenses and key certifications (like ISO 9001, UL, and RoHS), assessing their engineering capabilities, requesting and testing samples, and ideally, performing a factory audit to evaluate their quality control systems and production capacity before committing to a partnership.

Sourcing custom cables from China offers immense opportunities for cost-efficiency and access to massive production capabilities. However, navigating the landscape of thousands of potential suppliers can be daunting. The difference between a successful product launch and a costly failure often lies in the partner you choose. A reliable manufacturer is more than just a vendor; they are an extension of your business, a partner in quality and innovation. This comprehensive 2025 sourcing guide will walk you through every step of the process, equipping you with the knowledge to identify, vet, and build a lasting relationship with a top-tier Chinese cable manufacturer.

Table of Contents

- Part 1: The Foundation – Preparing for Your Search

- Part 2: Where to Find Potential Cable Manufacturers

- Part 3: The Critical Vetting Process – Separating Contenders from Pretenders

- Part 4: Engaging Your Chosen Partner – From RFQ to Mass Production

- Part 5: Future-Proofing Your Sourcing Strategy for 2025 and Beyond

- Conclusion: Building a Partnership, Not Just a Transaction

Part 1: The Foundation – Preparing for Your Search

Before you even type a single search query, the most important work begins internally. A poorly defined project will invariably lead to a poor outcome, regardless of the manufacturer’s quality. Laying a strong foundation by understanding your needs and clearly documenting them is the first step toward a successful sourcing journey. This preparation prevents miscommunication, reduces the risk of receiving incorrect products, and empowers you to negotiate from a position of strength.

What’s the Difference Between OEM and ODM for Cables?

Understanding the distinction between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) is fundamental to finding the right partner. Your choice will dictate the type of factory you need and the level of involvement required from your team.

- OEM (Original Equipment Manufacturer): You provide the complete design. In an OEM relationship, you are responsible for the research, development, and detailed engineering specifications of the cable. The Chinese factory acts as the manufacturing arm, building the product *exactly* to your specifications. This is the path for companies with unique, proprietary designs and in-house engineering expertise. You retain full intellectual property (IP) rights over your design.

- ODM (Original Design Manufacturer): You choose and modify an existing design. An ODM manufacturer already has a portfolio of pre-designed cable products. You select a base product from their catalog and request modifications, such as changing the connector type, cable length, color, or adding your branding. This approach is significantly faster and requires less R&D investment, making it ideal for businesses that need to get a product to market quickly without a completely novel design.

For 2025, many businesses are opting for a hybrid approach, leveraging an ODM’s base model but working closely with their engineers to add significant custom features. This balances speed-to-market with product differentiation. When you contact a potential supplier, be clear about whether you are seeking OEM or ODM services.

How to Define Your Cable Specifications Clearly

A “spec sheet” or technical data sheet is your project’s blueprint. The more detailed it is, the more accurate your quotes will be and the lower the risk of production errors. A vague request like “I need a USB-C cable” will get you nowhere. Instead, create a comprehensive document covering:

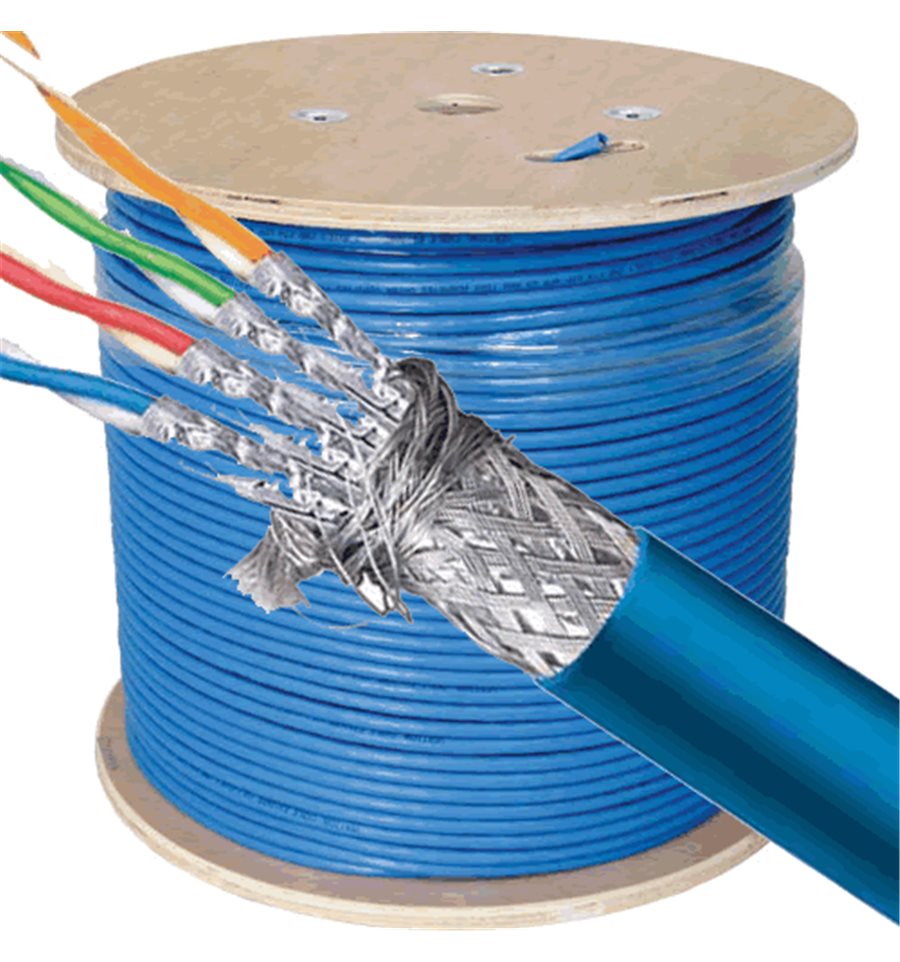

- Cable Type: (e.g., USB 3.1 Gen 2 Type-C, HDMI 2.1, Cat6a Ethernet, Custom multi-conductor cable)

- Conductors: Wire gauge (AWG), material (e.g., Tinned Copper, OFC), and stranding.

- Insulation & Jacket: Material (PVC, TPE, Nylon Braid), color (Pantone code), thickness, and durability requirements (e.g., bend-cycle rating).

- Connectors: Type (e.g., USB-A, Lightning, 5-pin DIN), material (e.g., Nickel-plated, Gold-plated), and overmold design.

- Electrical Properties: Required impedance, voltage rating, data transfer speed, and power delivery (e.g., 100W PD).

- Length and Tolerances: Specify the exact length and acceptable variance (e.g., 2m ± 20mm).

- Compliance: List required certifications (UL, CE, RoHS, MFi for Apple products).

- Packaging: How the final product should be packaged (polybag, retail box, master carton specs).

Having this document prepared will not only streamline your RFQ process but also instantly signal to potential manufacturers that you are a serious and professional buyer.

Part 2: Where to Find Potential Cable Manufacturers

With your specifications in hand, you can begin the search. The goal at this stage is to build a long list of potential suppliers that you will later narrow down. Diversifying your search channels is key to discovering a wide range of options, from massive factories to smaller, specialized workshops.

Leveraging Online B2B Platforms

Online marketplaces are the most common starting point for sourcing from China. They offer vast directories and communication tools. The main players include:

- Alibaba: The world’s largest B2B platform. Look for “Gold Suppliers” with a high number of years on the platform and “Verified” status, which indicates a third-party audit has been performed on their facilities.

- Made-in-China.com: Similar to Alibaba but often perceived as having a stronger focus on industrial and electronic components. Look for their “Audited Suppliers.”

- Global Sources: Known for connecting buyers with experienced, export-oriented manufacturers. They also host major trade shows.

When using these platforms, go beyond the front page. Use specific, long-tail keywords from your spec sheet (e.g., “braided USB-C PD 100W cable OEM”) to find specialists. Pay close attention to their company profile, product range, and response time.

The Power of Trade Shows and Industry Fairs

For making meaningful connections, nothing beats face-to-face interaction. Attending a trade show allows you to meet representatives, handle product samples, and ask in-depth questions. Key events for electronics and cables include:

-

- Canton Fair (Guangzhou): One of the largest trade fairs in the world, with a massive electronics section.

- Global Sources Consumer Electronics (Hong Kong): A major show focused on sourcing electronics from Asia.

–electronica China (Shanghai): A leading platform for electronic components, systems, and applications.

Even if you can’t attend in person, many shows now offer virtual components. Reviewing the exhibitor lists from these shows is an excellent way to identify leading and emerging manufacturers in the cable industry.

When Should You Consider a Sourcing Agent?

A sourcing agent or company can be an invaluable asset, especially for newcomers to Chinese manufacturing. They act as your on-the-ground representative, helping with supplier identification, communication, negotiation, and quality control. Consider an agent if:

- You have limited time or experience in sourcing from China.

- Your project is highly complex and requires close monitoring.

- You face significant language or cultural barriers.

A good agent leverages their network (guanxi) to find reputable factories that may not have a strong online presence. However, ensure you vet the agent themselves—ask for references and be clear on their commission structure.

Part 3: The Critical Vetting Process – Separating Contenders from Pretenders

This is where the real work begins. You’ve gathered a long list of 10-20 potential suppliers; now it’s time to systematically narrow it down to the top 2-3 contenders. A rigorous vetting process is your best defense against quality issues, production delays, and scams.

Initial Screening and Communication Assessment

Your first interaction is telling. Send a concise initial inquiry with your detailed spec sheet attached. Evaluate their response based on:

- Response Time: A professional company should respond within 24-48 hours.

- Clarity and Professionalism: Is the email well-written in English? Do they answer your questions directly or are they evasive?

- Technical Understanding: Do they ask intelligent questions about your specifications? This shows they have experienced engineers who have actually reviewed your request. A generic “Yes, we can do it” is a red flag.

This initial back-and-forth will quickly filter out unresponsive or unprofessional operations.

Why Verifying Certifications is Non-Negotiable

Certifications are not just logos on a website; they are proof of a manufacturer’s commitment to quality, safety, and environmental standards. Always ask for copies of their certificates and verify their validity. Key certifications for cable manufacturers include:

- ISO 9001:2015: This is the international standard for a Quality Management System (QMS). It doesn’t guarantee a perfect product, but it proves the factory has documented and repeatable processes for production, inspection, and continuous improvement. It’s a foundational requirement.

- UL (Underwriters Laboratories): Essential for products sold in North America. “UL Listed” applies to standalone products, while “UL Recognized” applies to components within a larger product. For cables, this certification indicates they have met stringent safety and fire-resistance standards.

- RoHS (Restriction of Hazardous Substances): Mandatory for products sold in the European Union. It restricts the use of specific hazardous materials like lead, mercury, and cadmium.

- CE Marking: A declaration that the product meets EU standards for health, safety, and environmental protection.

- Apple MFi (Made for iPhone/iPad/iPod): An absolute requirement if your cable has a Lightning connector. Unauthorized production can lead to performance issues and legal trouble. MFi-certified factories are subject to strict audits by Apple.

A reliable factory will provide these documents without hesitation. If they are evasive or provide expired certificates, eliminate them from your list.

Assessing Technical and Engineering Capability

A great manufacturer is an engineering partner. You need to gauge their ability to not only produce your cable but also to help you optimize it. Ask specific questions:

- “What is your R&D team’s experience with high-speed data cables like HDMI 2.1?”

- “Can you show us case studies of similar custom molding projects you’ve completed?”

- “What testing equipment do you have in-house?” (Look for network analyzers, TDR testers, bend testers, salt spray testers).

For an ODM project, their design portfolio speaks volumes. For an OEM project, their engineers’ ability to understand and provide feedback on your design is what matters most. A good partner might suggest a more durable material or a more efficient production method, adding value beyond simple manufacturing.

The Role of Samples and Prototypes

Never proceed to mass production without first approving samples. There are typically two stages:

- Stock Samples: Requesting existing products similar to yours. This is a quick and cheap way to assess their general quality level, materials, and feel.

- Pre-Production Prototypes: These are custom-made samples based on your exact specifications. You will likely have to pay a fee and tooling costs (for custom molds). This is a critical investment. Once you receive the prototype, test it rigorously against every point on your spec sheet. Check dimensions, electrical performance, durability, and aesthetics. Provide clear, documented feedback for any required revisions.

Do not approve the prototype until it is 100% correct. Any small flaw you approve at this stage will be replicated thousands of times in mass production.

Conducting a Thorough Factory Audit (Virtual or In-Person)

A factory audit is the ultimate verification step. While an in-person visit is ideal, a well-structured live video audit has become a viable and cost-effective alternative in 2025. You can hire a third-party inspection company or conduct it yourself. Your goal is to verify the claims made online and assess the reality on the ground.

| Category | What to Look For | Why It Matters |

|---|---|---|

| Production Lines | Cleanliness, organization (5S methodology), modern equipment (automated wire cutting, stripping, soldering). | An organized line minimizes errors and indicates a disciplined management style. Modern equipment improves consistency and quality. |

| Quality Control Stations | Are there dedicated QC points? (Incoming materials, in-process, final product testing). What equipment are they using? | Proves that quality is integrated into the process, not just an afterthought. Verifies their ability to test to your specs. |

| Warehouse | Organized storage of raw materials and finished goods. Climate control for sensitive components. Clear labeling and tracking. | Prevents material degradation and mix-ups. A chaotic warehouse is a major red flag for poor management. |

| Engineering & R&D Office | Do they have an actual engineering team? Are they using CAD software? Is there a lab for testing? | Confirms their technical capabilities and ability to solve problems, especially crucial for OEM projects. |

| Worker Conditions | Adequate lighting, safety equipment, general worker morale. | Ethical sourcing is crucial. Happy, well-treated workers produce better quality work. High turnover can lead to inconsistent quality. |

During the audit, ask to see their business license (to verify they are a manufacturer, not a trading company) and their quality control documentation. A trustworthy manufacturer will be proud to show you their operation.

Part 4: Engaging Your Chosen Partner – From RFQ to Mass Production

After your rigorous vetting, you should have one or two top contenders. Now you move into the formal engagement phase, where legal and financial commitments are made. Precision and clarity are paramount.

Crafting an Effective Request for Quotation (RFQ)

Send your final, detailed RFQ to your top choices. In addition to the technical spec sheet, your RFQ should request:

- Unit price based on different order quantities (MOQ, 5,000 units, 10,000 units).

- Cost for tooling/molds (as a one-time, separate line item).

- Cost for pre-production samples.

- Production lead time after sample approval.

- Payment terms (e.g., 30% deposit, 70% upon completion before shipping is standard).

- Shipping terms (Incoterms like FOB, EXW).

Negotiating Terms and Solidifying Contracts

Don’t just accept the first quote. There is often room for negotiation, but focus on value, not just the lowest price. You might negotiate for better payment terms, a lower MOQ, or faster lead times. Once terms are agreed upon, formalize everything in a bilingual manufacturing agreement. This contract should cover IP protection (especially for OEM), quality standards, payment schedules, lead times, and penalties for delays or quality failures. Have it reviewed by a lawyer familiar with Chinese business law.

Implementing a Robust Quality Control (QC) Strategy

Your responsibility for quality doesn’t end when you place the order. A multi-layered QC strategy is essential:

- Incoming Quality Control (IQC): The factory should be testing all raw materials (wires, connectors, plastics) before they enter the production line.

- In-Process Quality Control (IPQC): Checks at various stages of production (e.g., after soldering, after overmolding) to catch issues early.

- Final Quality Control (FQC): The factory’s own 100% testing of every finished cable before packaging.

- Your Pre-Shipment Inspection (PSI): This is *your* final check. Before you pay the final balance, you or a hired third-party inspector should go to the factory and inspect a random sample of the finished goods based on AQL (Acceptable Quality Limit) standards. This is your last chance to catch widespread issues before the products leave China.

Part 5: Future-Proofing Your Sourcing Strategy for 2025 and Beyond

The global manufacturing landscape is constantly evolving. A forward-thinking sourcing strategy for 2025 and beyond must consider new trends and risks. Discuss these topics with potential partners to gauge how prepared they are for the future:

- Automation and Smart Factories: Ask about their level of automation. Factories investing in automated soldering, testing, and assembly are better equipped to deliver consistent quality and scale production efficiently.

- Sustainability and Green Materials: As consumer demand for eco-friendly products grows, partnering with a manufacturer that has experience with recycled materials (rPET for braiding, recycled TPE) or biodegradable plastics can provide a significant market advantage. Ask about their waste management and energy efficiency programs.

- Supply Chain Resilience: The last few years have highlighted supply chain vulnerabilities. Ask your potential partner how they manage their own suppliers of raw materials. Do they have multiple sources for key components like chipsets or raw copper to mitigate the risk of disruption?

Conclusion: Building a Partnership, Not Just a Transaction

Choosing a reliable cable OEM/ODM manufacturer in China is not a simple transaction—it’s the beginning of a crucial business partnership. The cheapest option is rarely the best. The right partner is one who communicates clearly, demonstrates deep technical expertise, embraces quality as a core principle, and is willing to grow with you. By investing time and resources in the foundational preparation and rigorous vetting process outlined in this guide, you move beyond simply buying a product. You are building a resilient, high-quality supply chain that will serve as a cornerstone of your business’s success for years to come.