Introduction: The Need for Speed in the Digital Age

Data centers and smart factories need very high speeds. They often require 10 Gbps or even 40 Gbps. Standard insulation cannot handle these high frequencies well. The signal becomes weak over long distances.

At DLAY, we focus on high-speed cable technology. We use physical foaming to solve this problem. This technology is a game changer for CAT6A, CAT7, and CAT8 cables. It makes the data move faster and stay cleaner. This article explains the science behind this important technology.

What is Physical Foaming? Understanding the Micro-Level

Physical foaming is a special manufacturing process. We inject high-pressure nitrogen gas into the plastic insulation. This creates millions of tiny bubbles. These bubbles are very small and uniform.

In older cables, companies used chemical foaming. Chemical foaming uses heat to cause a reaction. But it leaves chemical residues. These residues hurt the electrical performance. Physical foaming is much cleaner. It creates a better environment for the signal.

| Feature | Chemical Foaming | Physical Foaming (DLAY) |

| Process | Chemical reaction | Nitrogen gas injection |

| Uniformity | Average | Extremely high |

| Foaming Rate | Up to 40% | Up to 75% – 80% |

| Residue | Leaves chemical salts | No residue, very pure |

Dive Deeper: The Physics of Signal Integrity

Lowering the Dielectric Constant (ε)

Every material has a dielectric constant. It measures how much a material resists an electric field. Solid plastic has a high constant. Air or nitrogen has a very low constant.

By adding nitrogen bubbles, we lower the total dielectric constant of the cable. A lower constant means the plastic absorbs less energy. This keeps the signal strong even at high frequencies.

Boosting the Velocity of Propagation (VOP)

Velocity of Propagation is the speed of the signal. In a perfect vacuum, signals move at the speed of light. In solid plastic, they move slowly.

Physical foaming increases the VOP. Our cables can reach a VOP of 80% or higher. This means your data reaches the destination faster. It reduces “latency” in high-speed networks.

Comparison: Why Foam is Better than Solid Insulation

Solid insulation is heavy and stiff. It also has high capacitance. This is bad for high-speed data. Physical foaming makes the cable lighter. It also makes it easier to bend without breaking the internal structure.

| Technical Metric | Solid PE Insulation | Physical Foam PE (DLAY) |

| Dielectric Constant | ~2.3 | ~1.5 |

| Attenuation (Signal Loss) | High | Very Low |

| Cable Weight | Heavy | Light |

| Signal Speed (VOP) | ~66% | ~80%+ |

Manufacturing Excellence: The DLAY Four-Layer Co-Extrusion

The Skin-Foam-Skin Structure

We use advanced machines at DLAY. Our lines run at 1000m/min. We create a “Skin-Foam-Skin” structure.

-

Outer Skin: A thin layer of solid plastic for toughness.

-

Foam Layer: The nitrogen-rich layer for speed.

-

Inner Skin: A layer that sticks to the copper conductor.

This structure protects the bubbles. It ensures the cable does not lose its shape when you pull it through a wall. It combines electrical speed with physical strength.

Applications: Where Physical Foaming is Mandatory

Data Centers and CAT6A/CAT7/CAT8

In data centers, you cannot have signal errors. We use physical foaming for all our CAT6A and CAT7 cables. These cables support 10G networks.

Industrial Automation

Robots move all the time. They need flexible cables. Physical foaming makes the insulation flexible. It also protects the data from the noise of big motors.

Consistency is Key: Why DLAY Leads the Market

Eliminating Crosstalk with Uniformity

If the bubbles are not uniform, the signal will bounce back. This is called “Return Loss.” Our technology ensures every inch of the cable is the same. This uniformity is why our cables pass the Fluke test easily.

We monitor the foaming process in real-time. We adjust the gas pressure and temperature every second. This gives our customers a stable and reliable product.

The Future of High-Frequency Transmission

Cables are moving toward 40Gbps and 100Gbps. At these speeds, even the smallest mistake matters. Physical foaming is the only way to reach these goals. It is the foundation of future networking.

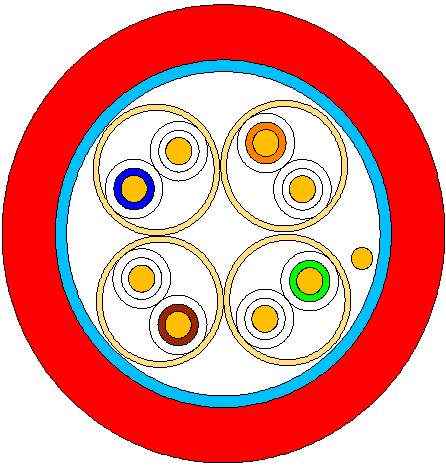

How to Choose a Physical Foaming Cable

Always ask your supplier for a cross-section image. You should see tiny, equal bubbles. If the bubbles are large or different sizes, the cable is low quality. At DLAY, we provide 100% transparency on our manufacturing quality.

Conclusion

Physical foaming is a vital science. It lowers the dielectric constant and increases signal speed. It makes cables lighter and more flexible. DLAY uses four-layer co-extrusion to provide the best foaming quality in the industry. We help you stay connected at the highest speeds possible.